We know that it's very important for a company to avoid storing products for extended periods, as the longer they remain in storage, the more value they lose. Furthermore, storing products can lead to changes in demand, breakage, losses, or theft, in addition to the obvious decrease in value.

To avoid these problems, we offer E-Pack intelligent warehouse management. It's a tool that will improve your operations. warehouse mobility, and will allow for increased efficiency, optimized spaces, and improved performance.

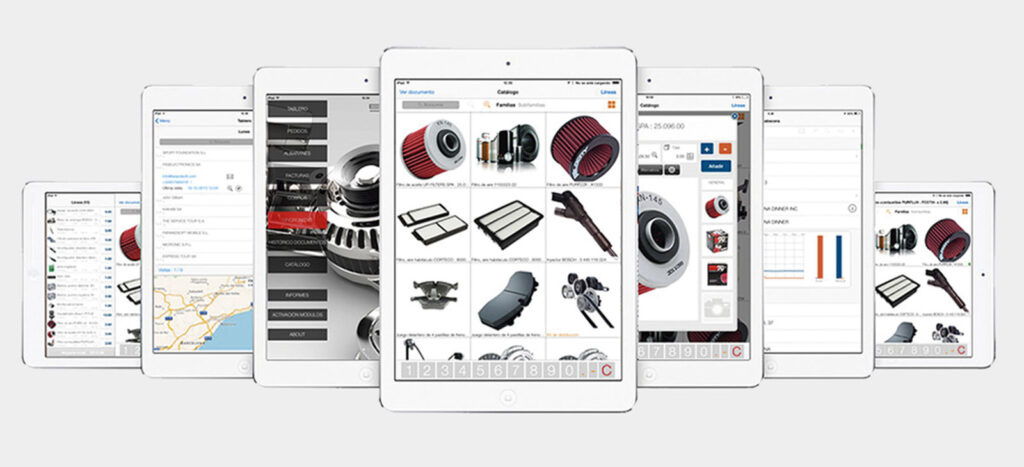

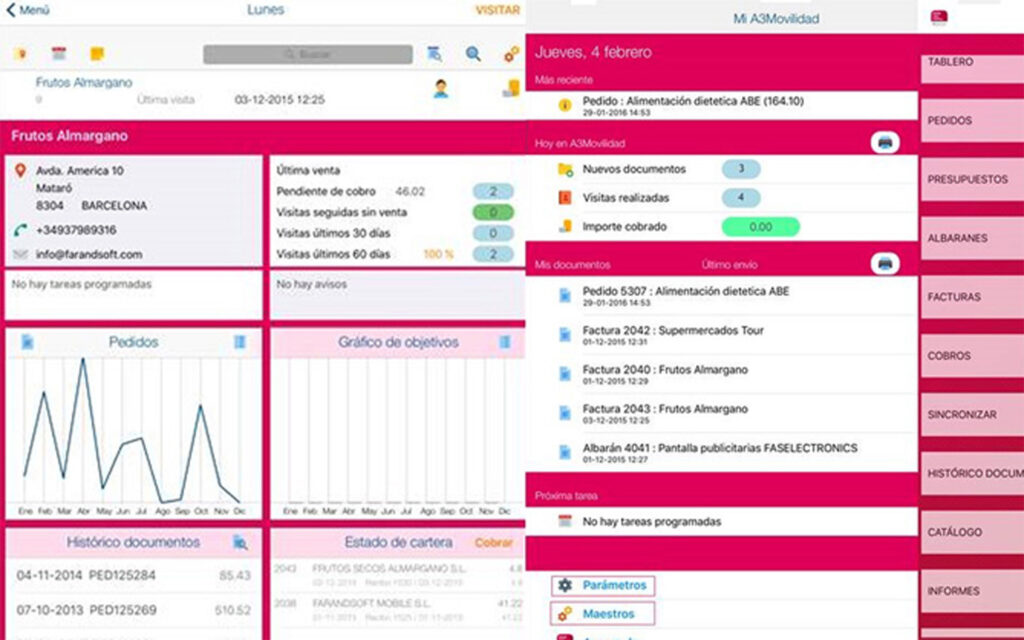

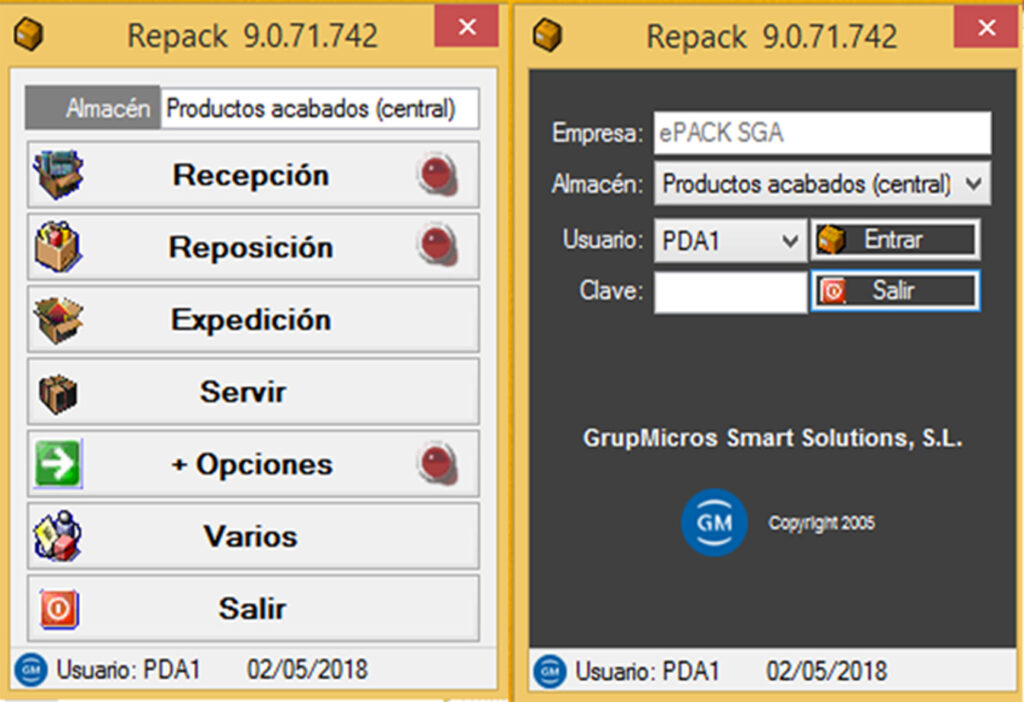

The main functionalities offered by the E-Pack warehouse management system are based on two applications: one for PC, integrated with the a3ERP management software for warehouse management and planning, and another application for mobile phones to facilitate the warehouse mobility. This last feature will allow you to carry out planned tasks from the same location, thus improving the optimization of physical space. Furthermore, it keeps the warehouse inventory updated at all times, achieving greater efficiency in all processes. We will focus more on the mobile application, as this is the part that improves the warehouse mobility.

Barcodes are a key aspect for controlling warehouse stock, because with E-Pack you will have EAN128 and Damatrix to classify all items.

On one hand, it offers the Picking tool, which increases the efficiency and effectiveness of order preparation. It organizes pickers according to the type of picking required and sends immediate orders after the completion of the current picking order. The real-time operating system allows for automatic updates of information and real-time stock availability.

It also reduces restocking wait times by sending orders to the operator's mobile terminal, eliminating the need for movement and ensuring that all trips are productive. In addition to increasing operator productivity by optimizing routes and movements, it also reduces picking errors and minimizes product replenishment trips, thus optimizing movement within the system. warehouse mobility.

On the other hand, cross-docking is another optimization method. warehouse mobility, This system reduces duplicate movements when preparing orders or transfer requests in the warehouse. It allows for the recording of information on goods that have arrived from one or more trucks and have been loaded onto other trucks with different routes. The operator simultaneously manages the entry and exit of goods to their destination. Similarly, it reduces transit times for goods within the warehouse and controls the cross-docking process, identifying any discrepancies against the truck's cargo record in the computer system.